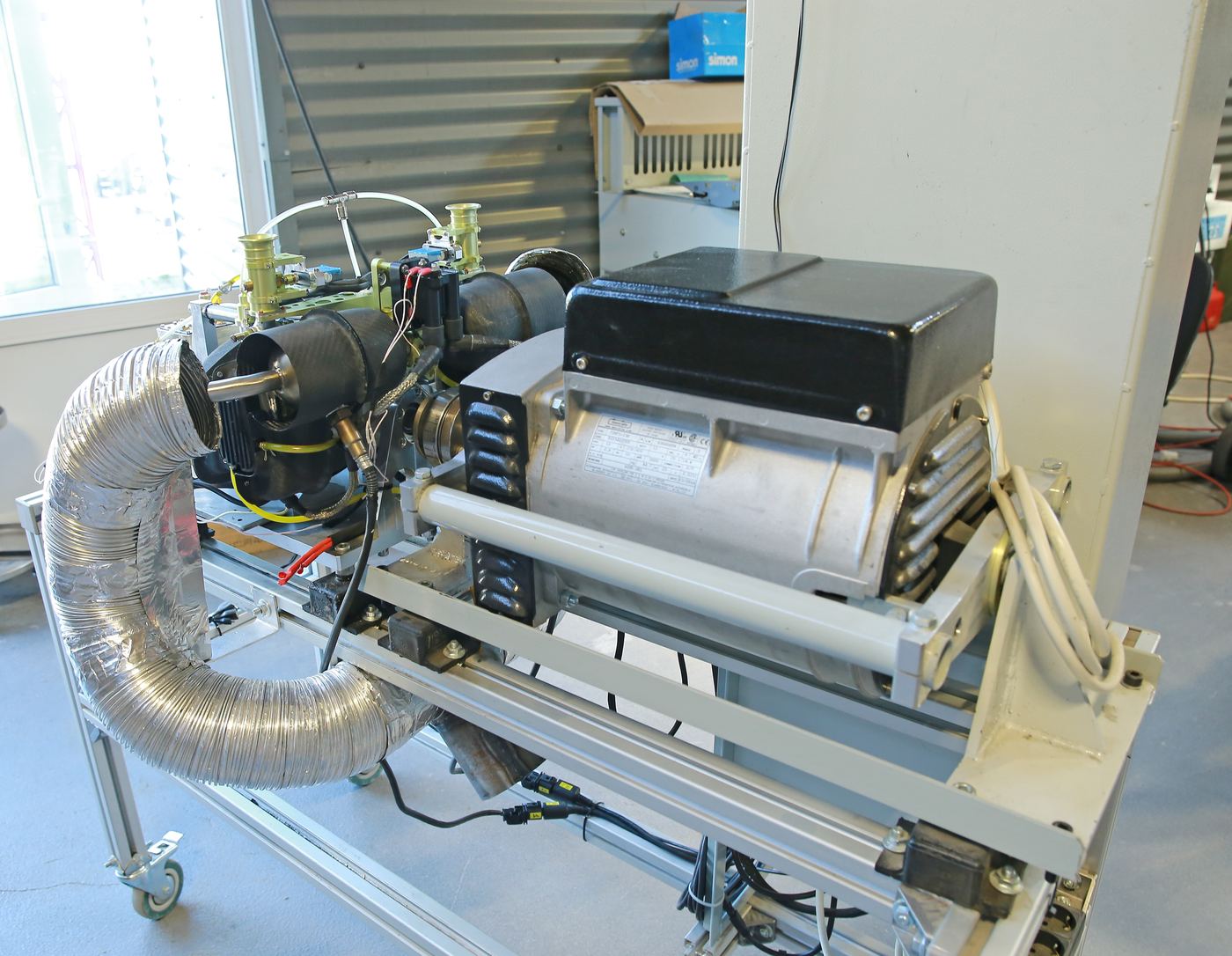

Test Bed For Load And Diagnostic Tests Of Internal Combustion Engines And Electric Motors With Remote Control

For reliable operation of its UAVs, UAVOS uses equipment for testing and trial runs of internal combustion engines with a maximum power of up to 25hp. The equipment was designed by UAVOS taking into account the specifics of the operation of engines in unmanned aircraft.

All essential engine parameters are displayed on a computer monitor:

- Rotation velocity

- Torque

- Power

- Engine temperature

- Exhaust temperature

- The composition of the air-fuel mixture, etc.

Capability of multi cylinder engine test bed with remote control:

- Measure maximum torque and maximum power

- Analysis of part load torque and nominal loads

- Analyze efficiency & fuel consumption characteristics at varying speed & load

- Measure engine temperature

- Measure exhaust temperature

- Determine the optimum ignition timing angle

- Determination air-to-fuel ratio

- Fine-tune and calibrate the injection system

Based on the data obtained, graphs of power, torque, thermal efficiency, fuel consumption are built. If necessary, the test bed is equipped with its own system for cooling the engine under a test run. To ensure safe testing, the functions of protection against excessively high speeds, overheating or engine overload are used.

All parameters are processed by UAVOS software.

“This is just another example of how we are working to reduce risk and make better performance improving engines reliability and endurance. Engine Test Bed allows us to deliver maximum mission-ready availability and bottom-line value to our customers – helping to reduce maintenance schedules and lower operating costs. Our engines allow customers to fly longer with superior performance. There is hope that our engines will open new customer and platform opportunities” - comments Aliaksei Stratsilatau, CEO, UAVOS.

17 October 2019